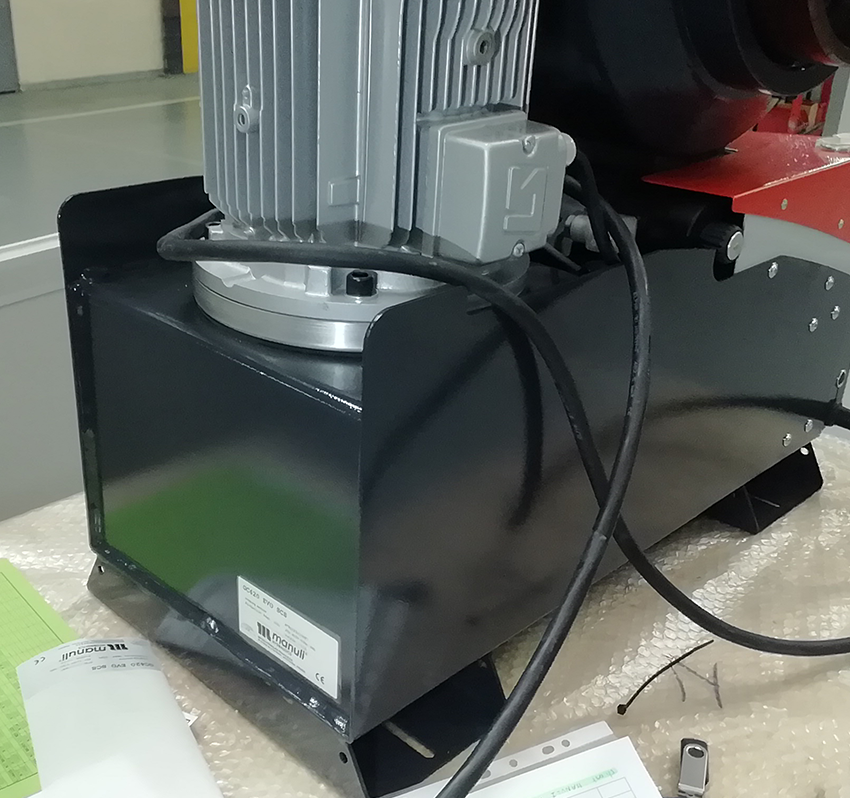

Location of Serial Number

Serial number is of the format "A1234567890"

Serial Number can also be found under the electronics panel cover

|

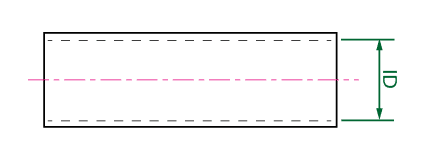

TEXTILE SLEEVE TSL |

| PART. REF | DESCRIPTION | DIMENSIONS | |||||||

| INTERNAL DIAMETER (ID) |

EXTERNAL FLATTENED WIDTH |

WEIGHT | STANDARD PACK LENGTH |

||||||

| mm | in | mm | in | g/m | lb/ft | m | ft | ||

| JP23B06018I099 | TEXTILE SLEEVE DN 18 | 18.0 | 0.71 | 32.0 | 1.26 | 2.0 | 4.4 | 50 | 165 |

| JP23B06023I099 | TEXTILE SLEEVE DN 23 | 23.0 | 0.91 | 40.0 | 1.57 | 2.2 | 4.8 | 50 | 165 |

| JP23B06029I099 | TEXTILE SLEEVE DN 29 | 29.0 | 1.14 | 49.0 | 1.93 | 2.5 | 5.5 | 50 | 165 |

| JP23B06036I099 | TEXTILE SLEEVE DN 36 | 36.0 | 1.42 | 56.0 | 2.20 | 3.0 | 6.6 | 50 | 165 |

| JP23B06040I099 | TEXTILE SLEEVE DN 40 | 40.0 | 1.57 | 63.0 | 2.48 | 3.2 | 7.0 | 50 | 165 |

| JP23B06056I099 | TEXTILE SLEEVE DN 56 | 56.0 | 2.20 | 88.0 | 3.46 | 4.0 | 8.8 | 50 | 165 |

| JP23B06063I099 | TEXTILE SLEEVE DN 63 | 63.0 | 2.48 | 105.0 | 4.13 | 5.0 | 11.0 | 50 | 165 |

| JP23B06071I099 | TEXTILE SLEEVE DN 71 | 70.0 | 2.80 | 115.0 | 4.53 | 5.5 | 12.1 | 50 | 165 |

| JP23B06093I099 | TEXTILE SLEEVE DN 93 | 93.0 | 3.66 | 146.0 | 5.75 | 7.2 | 15.8 | 50 | 165 |

| JP23B06110I099 | TEXTILE SLEEVE DN 110 | 110.0 | 4.33 | 176.0 | 6.93 | 8.5 | 18.7 | 50 | 165 |

• High abrasion resistance

• Resistant to water, oils, fuels and hydraulic fluids

• Fluid energy diffusion in case of hose failure to prevent direct jetting

• Easy to install with simple clamps to extremities

• Flame retardant and antistatic properties

-50 °C, -58 °F

100 °C, 212 °F

140 °C, 284 °F

Polyester fibres

Manuli® Design, MSHA, FRAS, MDG41