Location of Serial Number

Serial number is of the format "A1234567890"

Serial Number can also be found under the electronics panel cover

|

TECHNICAL DATA |

|||||||||||||||||

|

SIZE |

WORKING |

RATED FLOW |

CONNECTION |

OIL SPILLAGE |

MINIMUM BURST PRESSURE |

CONNECTION / |

|||||||||||

|

DN |

inch |

Dash |

MPa |

PSI |

l/min |

US |

N |

lb. |

cc. |

cubic |

Male |

Female |

M & F |

||||

|

MPa |

PSI |

MPa |

PSI |

MPa |

PSI |

||||||||||||

| 6 | 1/4 | 4 | 30 | 4,350 | 9 | 2.4 | 40 | 8.9 | 0.35 | 0.021 | 140 | 20,300 | 125 | 18,125 | 150 | 21,750 | Not allowed |

| 10 | 3/8 | 6 | 25 | 3,625 | 25 | 7.4 | 65 | 14.4 | 0.85 | 0.052 | 115 | 16,675 | 120 | 17,400 | 160 | 23,200 | Not allowed |

| 12 | 1/2 | 8 | See ISO A Series | ||||||||||||||

| 19 | 3/4 | 12 | 25 | 3,625 | 74 | 19.6 | 75 | 16.7 | 3.5 | 0.214 | 100 | 14,500 | 110 | 15,950 | 125 | 18,125 | Not allowed |

| 25 | 1 | 16 | 21 | 3,045 | 114 | 30.1 | 100 | 22.2 | 5.0 | 0.305 | 100 | 12,325 | 100 | 14,500 | 110 | 15,950 | Not allowed |

| The rated flow represents the normal operating condition. The maximum recommended flow rate is equal to 1.5 times the rated flow | |||||||||||||||||

• Historical series for the agriculture market

• Simple connection and disconnection by pulling back the sleeve

• Positive, quick connection of the male into the female by latching the ball system

• Shut-off by ball valve

• High resistant materials

• Interchangeable with poppet valve standard series and with similar products available on the market (½” size according to ISO 7241-1 series A)

Female couplings in steel, with some hardened areas, in correspondence to the most stressed points. Male couplings in high grade carbon steel hardened. High-resistance latching balls, springs in C98 steel, seals in NBR and back-up ring in PTFE

-22ºF up to +230ºF (-30ºC up to +110ºC)

For other temperatures, the coupling may be assembled with the specific seals

4:1 for dynamic pressures

100,000 cycles at 133% of the rated one (freq. 1Hz)

ISO 18869

| BSP | ||||

| Q03311041A / Q03011041A | Q03311041B / Q03011041B | |||

|

Q03311041A Q03011041A |

||||||||||

| BSP TERMINATION ENDS TO DIN 3852 X TYPE |

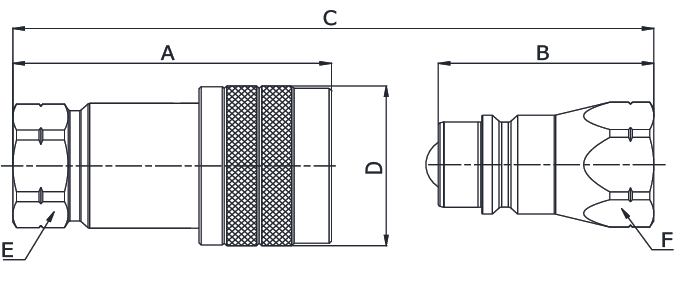

| SIZE | PART NUMBER | THREAD | DIMENSIONS mm | ||||||||

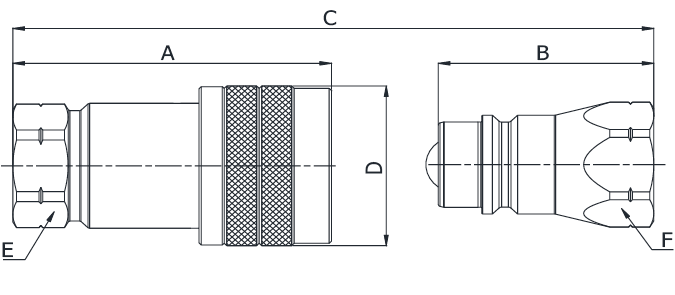

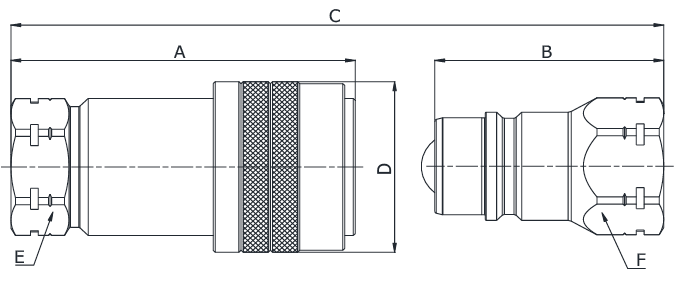

| DN | Inch | Dash | Female coupling | Male coupling | A | B | C | D | E | F | |

| 6.3 | 1/4" | -04 | Q03311041A-04-04 | Q03010041A-04-04 | 1/4" | 51.3 | 34.3 | A+B-16,6 | ⌀27 | 19 | 19 |

| 10 | 3/8" | -06 | Q03311041A-06-06 | Q03010041A-06-06 | 3/8" | 59.9 | 39.4 | A+B-20,1 | ⌀34 | 24 | 24 |

| 12.5 | 1/2" | -08 | SEE ISO SERIES A | ||||||||

| 20 | 3/4" | -12 | Q03311041A-12-12 | Q03010041A-12-12 | 3/4" | 85.5 | 56.5 | A+B-28,3 | ⌀47 | 34 | 34 |

| 25 | 1" | -16 | Q03311041A-16-16 | Q03010041A-16-16 | 1" | 98 | 64.5 | A+B-32,9 | ⌀52 | 41 | 41 |

|

Q03311041B Q03011041B |

||||||||||

| BSP TERMINATION ENDS TO DIN 3852 X TYPE |

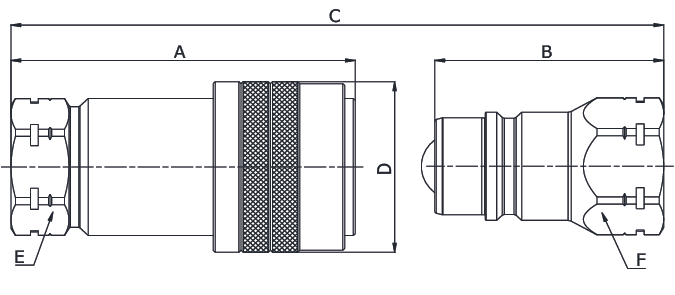

| SIZE | PART NUMBER | THREAD | DIMENSIONS mm | ||||||||

| DN | Inch | Dash | Female coupling | Male coupling | A | B | C | D | E | F | |

| 20 | 3/4" | -12 | Q03311041B-12-12 | Q03010041B-12-12 | 3/4" | 88 | 58.5 | A+B-31,5 | ⌀47 | 34 | 34 |

| NPT | ||||

| Q03311341A Q03011341A |

Q03311341B Q03011341B |

|||

|

Q03311341A Q03011341A |

||||||||||

| NPTF TERMINATION END TO ANSI B 1.20.3 |

| SIZE | PART NUMBER | THREAD | DIMENSIONS mm | ||||||||

| DN | Inch | Dash | Female coupling | Male coupling | A | B | C | D | E | F | |

| 6.3 | 1/4" | -04 | Q03311341A-04-04 | Q03010341A-04-04 | 1/4" NPTF | 51.3 | 34.3 | A+B-16,6 | ⌀27 | 19 | 19 |

| 10 | 3/8" | -06 | Q03311341A-06-06 | Q03010341A-06-06 | 3/8" NPTF | 59.9 | 39.4 | A+B-20,1 | ⌀34 | 24 | 24 |

| 12.5 | 1/2" | -08 | SEE ISO SERIES A | ||||||||

| 20 | 3/4" | -12 | Q03311341A-12-12 | Q03010341A-12-12 | 3/4" NPTF | 85.5 | 56.5 | A+B-28,3 | ⌀47 | 34 | 34 |

| 25 | 1" | -16 | Q03311341A-16-16 | Q03010341A-16-16 | 1" NPTF | 98 | 64.5 | A+B-32,9 | ⌀52 | 41 | 41 |

|

Q03311341B Q03011341B |

||||||||||

| NPTF TERMINATION END TO ANSI B 1.20.3 |

| SIZE | PART NUMBER | THREAD | DIMENSIONS mm | ||||||||

| DN | Inch | Dash | Female coupling | Male coupling | A | B | C | D | E | F | |

| 6.3 | 1/4" | -04 | Q03311341B-12-12 | Q03010341B-12-12 | 3/4" NPTF | 88 | 58.5 | A+B-31,5 | ⌀47 | 34 | 34 |