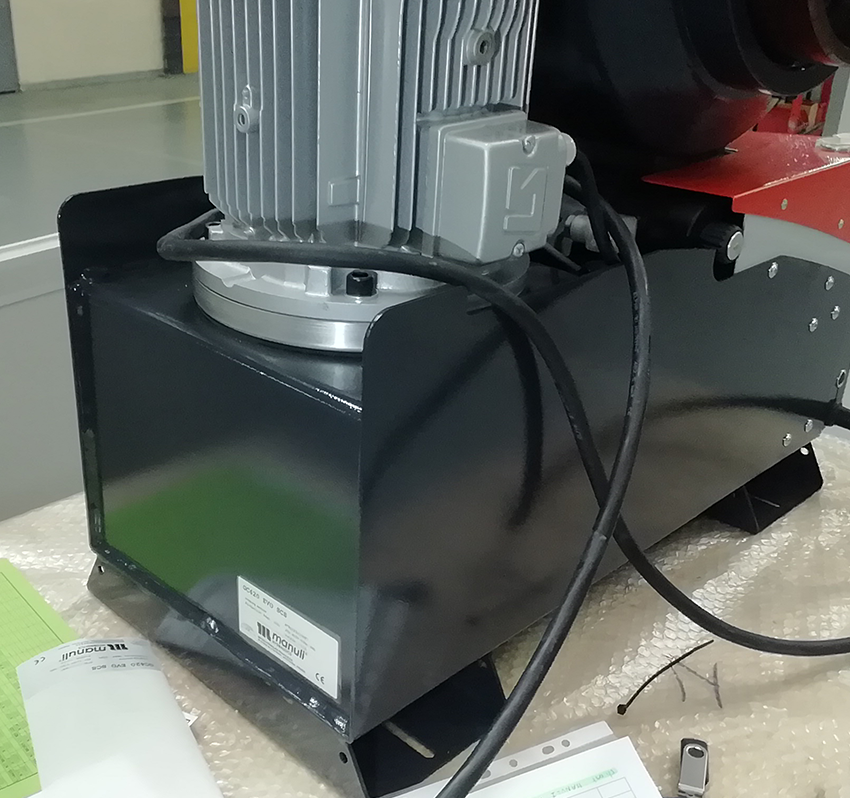

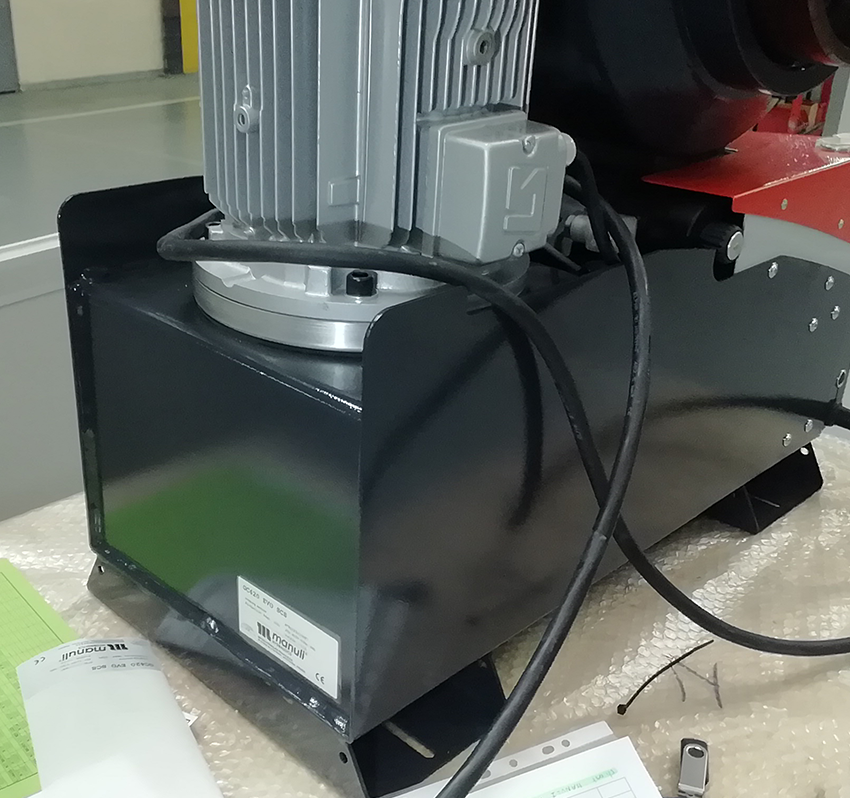

Location of Serial Number

Serial number is of the format "A1234567890"

Serial Number can also be found under the electronics panel cover

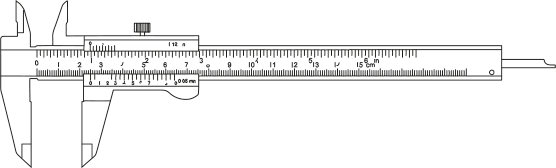

| TECHNICAL DATA | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|||||||||

| PART REF. | HOSE SIZE | R.O.D | O.D | MAX. W.P | BURST | MIN. BEND | WEIGHT | FITTINGS | |||||||||

| DN | dash | inch | mm | inch | mm | inch | bar | psi | bar | psi | mm | inch | g/m | lb/ft | Std 1 | Std 2 | |

| H10089006* | 6 | -4 | 1/4" | 14.7 | 0.58 | 17.1 | 0.67 | 460 | 6,670 | 1,840 | 26,680 | 125 | 4.92 | 567 | 0.38 | IP+M01500-04 | – |

| H10089016* | 16 | -10 | 5/8" | 25.5 | 1.00 | 28.5 | 1.12 | 460 | 6,670 | 1,840 | 26,680 | 250 | 9.84 | 1,290 | 0.87 | IP+M01500-10 | – |

| H10089019* | 19 | -12 | 3/4" | 28.4 | 1.12 | 32.0 | 1.26 | 460 | 6,670 | 1,840 | 26,680 | 280 | 11.02 | 1,530 | 1.03 | IP+M01500-12 | – |

| H10089025* | 25 | -16 | 1" | 35.4 | 1.39 | 38.2 | 1.50 | 460 | 6,670 | 1,840 | 26,680 | 340 | 13.39 | 2,150 | 1.44 | IP+M01500-16 | – |

| H10089031* | 31 | -20 | 1.1/4" | 46.3 | 1.82 | 49.5 | 1.95 | 450 | 6,520 | 1,800 | 26,100 | 420 | 16.54 | 3,790 | 2.55 | IP+M01800-20 | – |

| H10089038* | 38 | -24 | 1.1/2” | 54.2 | 2.13 | 58.0 | 2.28 | 450 | 6,520 | 1,800 | 26,100 | 450 | 17.72 | 5,002 | 3.36 | IP+M01600-24 | – |

• Designed for original equipment

• Long-term mission profile in severe applications

• Over standard pressure rating

• High impulse resistance exceeding the ISO 18752 requirements

• Superior abrasion resistance

• High ozone and weather resistance

• Flame retardant and antistatic properties of the cover

• Wide compatibility with hydraulic fluids, mineral and biodegradable oils

• Low bend radius, better than the standard requirements

• Interlock-Plus easy mounting system for a very high-level robustness

• Isobaric pressure rating for easy selection and product management

• Heavy duty pressure lines, hydrostatic transmissions, heavy duty earth moving equipment, hydraulic presses, drilling applications, injection moulding machines, specific installations with severe abrasion conditions and/or harsh environmental conditions, marine applications, underground and open pit mining

• Mineral oils, vegetable oils and synthetic ester based oils (up to 100°C/212°F), glycols and polyglycols, mineral oils in aqueous emulsion, water

-40 °C, -40 °F

121 °C, 250 °F

Oil resistant synthetic rubber

Four high tensile steel wire spirals (DN 6-25). Six high tensile steel wire spirals (DN 31-38)

STRONG – TYPE “SC”

Synthetic rubber with high abrasion, ozone, weather and heat resistance and an extended operational temperature range

Manuli® Design exceeds SAE J517 Type 100R15;

ISO 3862 R15; ISO 18752-D extension

CU-TR; MSHA; FRAS

Location of Serial Number

Serial number is of the format "A1234567890"

Serial Number can also be found under the electronics panel cover