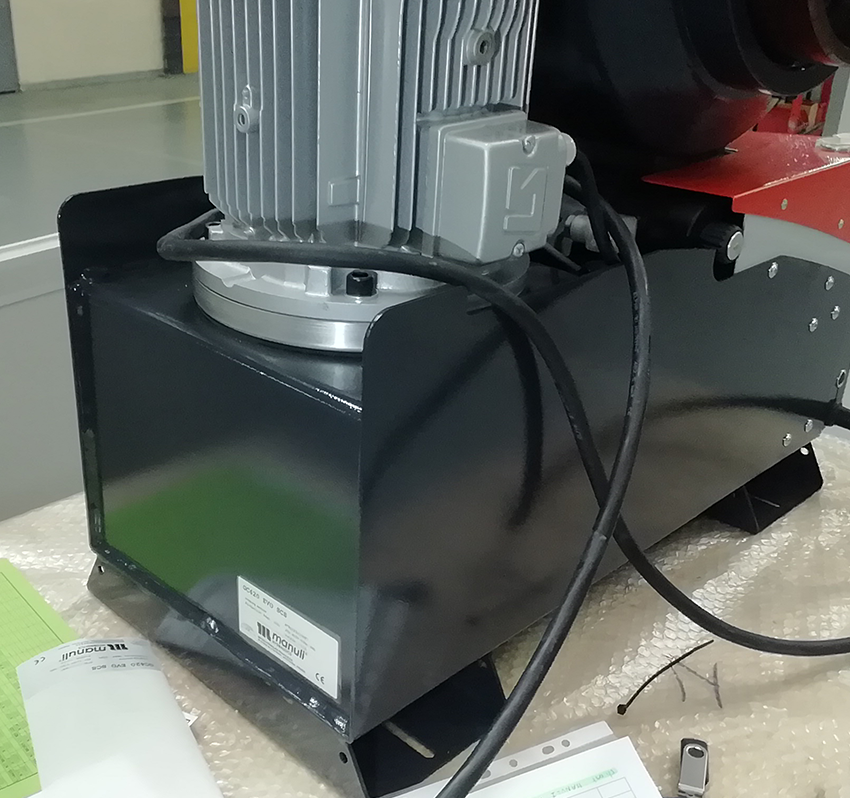

Location of Serial Number

Serial number is of the format “A1234567890”

Serial Number can also be found under the electronics panel cover

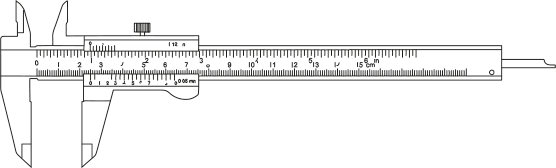

| TECHNICAL DATA | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|||||||||

| PART REF. | HOSE SIZE | R.O.D | O.D | MAX. W.P | BURST | MIN. BEND | WEIGHT | FITTINGS | |||||||||

| DN | dash | inch | mm | inch | mm | inch | bar | psi | bar | psi | mm | inch | g/m | lb/ft | Std 1 | Std 2 | |

| H10066010 | 10 | -6 | 3/8" | 17.4 | 0.69 | 20.0 | 0.79 | 1,250 | 18,120 | 3,125 | 45,320 | 230 | 9.06 | 800 | 0.54 | BL+M01700-06 | |

| H10066A12 | 12 | -8 | 1/2" | 21.5 | 0.85 | 24.1 | 0.95 | 1,100 | 15,950 | 2,750 | 39,880 | 230 | 9.06 | 1,110 | 0.75 | BL+M01700-08 | |

| H10066019 | 19 | -12 | 3/4" | 29.0 | 1.14 | 32.0 | 1.26 | 1,000 | 14,500 | 2,500 | 36,250 | 250 | 9.84 | 1,730 | 1.16 | BL+M01700-12 | |

| H10066025 | 25 | -16 | 1" | 35.1 | 1.38 | 38.1 | 1.50 | 700 | 10,150 | 1,750 | 25,380 | 250 | 9.84 | 2,040 | 1.37 | BL+M01500-16 | |

• Hose line for waterblasting with pressures up to 1250 bar

• Compactness, lightness and flexibility

• Safety factor 2,5:1 (accepted world standard as specified by RMA-USA, BFPA-UK, DIN-Germany, ISO 7751)

• High abrasion resistant cover

• Waterblasting, scale removing applications using extreme high working pressures:

• Building and industrial sectors (roadworks, removal of concrete from reinforced concrete structures safeguarding metal components);

• Scale removal ships hulls in shipyard;

• Dust elimination

• Water, water soap, emulsions

-10 °C, 15 °F

70 °C, 158 °F

Water resistant synthetic rubber

Four high tensile steel spirals

Synthetic rubber with very high temperature, ozone and abrasion resistance

Manuli® Design, Australian Std. AS/NZS 4233.2

CU-TR; MSHA