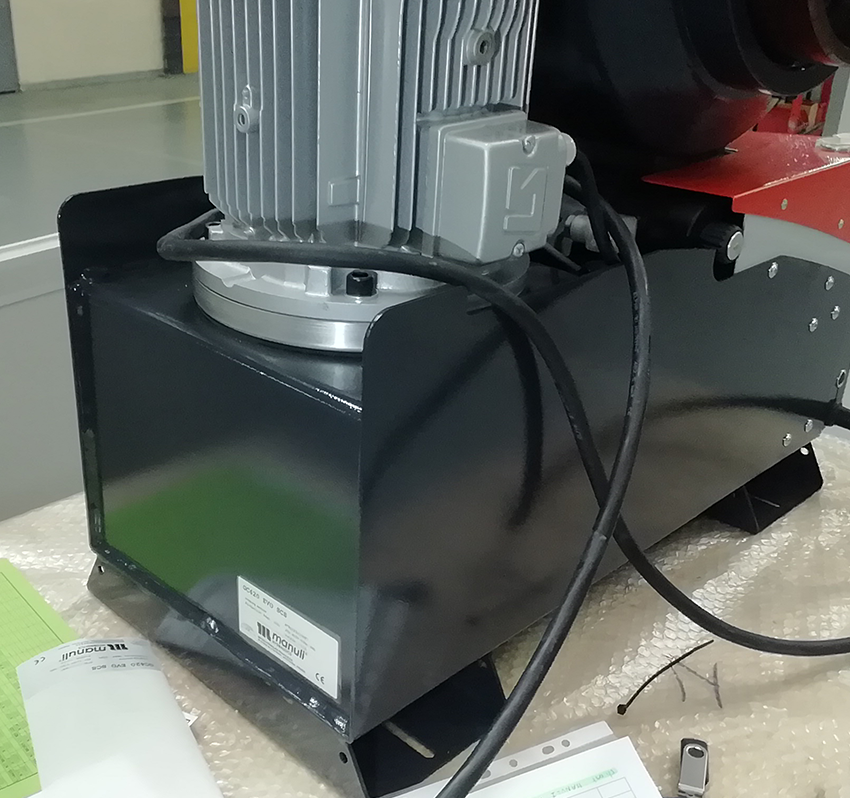

Location of Serial Number

Serial number is of the format "A1234567890"

Serial Number can also be found under the electronics panel cover

|

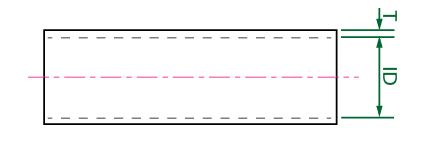

FIRE SLEEVE FSL |

| PART. REF | DESCRIPTION | DIMENSIONS | |||||||

| INTERNAL DIAMETER (ID) |

APPROX. WALL THICKNESS (T) |

WEIGHT | STANDARD PACK LENGTH |

||||||

| mm | in | mm | in | g/m | lb/ft | m | ft | ||

| JP24A05013I099 | FIRE SLEEVE DN 13 | 13.0 | 0.51 | 4.0 | 0.16 | 200.0 | 0.13 | 50 | 165.0 |

| JP24A05016I099 | FIRE SLEEVE DN 16 | 16.0 | 0.63 | 4.0 | 0.16 | 220.0 | 0.15 | 50 | 165.0 |

| JP24A05019I099 | FIRE SLEEVE DN 19 | 19.0 | 0.75 | 4.0 | 0.16 | 240.0 | 0.16 | 50 | 165.0 |

| JP24A05022I099 | FIRE SLEEVE DN 22 | 22.0 | 0.87 | 4.0 | 0.16 | 260.0 | 0.17 | 50 | 165.0 |

| JP24A05025I099 | FIRE SLEEVE DN 25 | 25.0 | 0.98 | 4.0 | 0.16 | 290.0 | 0.19 | 50 | 165.0 |

| JP24A05032I099 | FIRE SLEEVE DN 32 | 32.0 | 1.26 | 4.0 | 0.16 | 380.0 | 0.26 | 50 | 165.0 |

| JP24A05038I099 | FIRE SLEEVE DN 38 | 38.0 | 1.50 | 4.0 | 0.16 | 440.0 | 0.30 | 50 | 165.0 |

| JP24A05045I099 | FIRE SLEEVE DN 45 | 45.0 | 1.77 | 4.0 | 0.16 | 490.0 | 0.33 | 25 | 82.5 |

| JP24A05051I099 | FIRE SLEEVE DN 51 | 51.0 | 2.01 | 4.0 | 0.16 | 540.0 | 0.36 | 25 | 82.5 |

| JP24A05064I099 | FIRE SLEEVE DN 64 | 64.0 | 2.52 | 4.0 | 0.16 | 680.0 | 0.46 | 20 | 66.0 |

| JP24A05076I099 | FIRE SLEEVE DN 76 | 76.0 | 2.99 | 4.0 | 0.16 | 880.0 | 0.59 | 20 | 66.0 |

• Extreme heat resistance

• Extreme flexibility at low temperatures

• Designed to protect and insulate hydraulic hoses and bundles of hoses against flames, metal projections, melting glass etc.

• Easy to install, no clamps needed

-60 °C, -76 °F

260 °C, 500 °F

1100 °C, 2012 °F for 15 minutes; 1500 °C, 2732 °F for 1 minute

Silicone sleeve with glass-fibre braid

Manuli® Design, NFF16-101 and P92-507 (class FO and M2)