| TECHNICAL DATA | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|||||||||

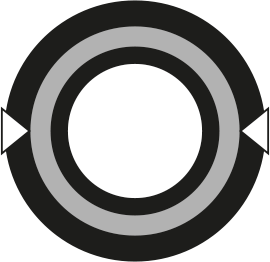

| PART REF. | HOSE SIZE | R.O.D | O.D | MAX. W.P | BURST | MIN. BEND | WEIGHT | FITTINGS | |||||||||

| DN | dash | inch | mm | inch | mm | inch | bar | psi | bar | psi | mm | inch | g/m | lb/ft | Std 1 | Std 2 | |

| H01112A12* | 12 | -8 | 1/2" | 18.5 | 0.73 | 22.5 | 0.89 | 310 | 4,490 | 1,240 | 17,980 | 80 | 3.15 | 1,220 | 0.82 | MF+M00120-08 | – |

| H01112016* | 16 | -10 | 5/8” | 22.7 | 0.89 | 26.3 | 1.04 | 280 | 4,060 | 1,120 | 16,240 | 90 | 3.54 | 1,640 | 1.10 | MF+M00120-10 | – |

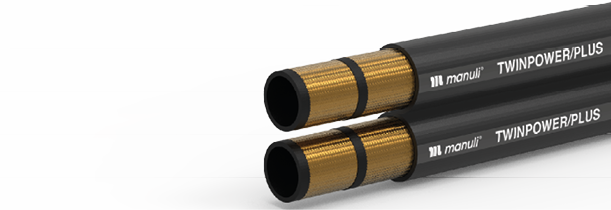

KEY FEATURES

• Compact hose structure and reduced bend radius

• Approved with 500.000 flexing impulse cycles (1,33 WP), 125.000 flexing cycles (Manuli® testing method)

• Smooth hose cover ensuring user friendly installation inside the booms

• Unique hose assembly solution for pressure and discharge line on the same body valve

• Reduced installation time compared to two separated assembly hose solutions

• Reduced risk of abrasion of the line inside the booms due to twin hose alignment

• Elimination of clamps to connect the two hose lines, with consequent easiness of insertion

• Higher abrasion resistant and flame retardant MSHA approved cover

• Warehouse/logistic optimization with reduced codes in stock

APPLICATIONS & FLUIDS

• Hydraulics: hose range dedicated to aerial lifts, platforms, forklift trucks and telescopic booms applications

• Mineral oils, vegetable oils and synthetic ester based oils, glycols and polyglycols, mineral oils in aqueous emulsion, water

CONTINUOUS SERVICE TEMPERATURE RANGE

-40 °C, -40 °F

121 °C, 250 °F

TUBE

Synthetic rubber

REINFORCEMENT

Two high tensile steel wire braids

COVER

STRONG – TYPE “SD”

Synthetic rubber with high abrasion, ozone, weather and heat resistance

APPLICABLE SPECS

Exceeds ISO 11237 2SC/R16; EN 857 2SC; SAE J517 Type 100R16

TYPE APPROVALS

CU-TR; MSHA