| TECHNICAL DATA | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|||||||||

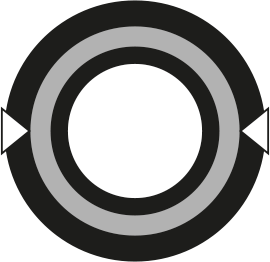

| PART REF. | HOSE SIZE | R.O.D | O.D | MAX. W.P | BURST | MIN. BEND | WEIGHT | FITTINGS | |||||||||

| DN | dash | inch | mm | inch | mm | inch | bar | psi | bar | psi | mm | inch | g/m | lb/ft | Std 1 | Std 2 | |

| H10120006* | 6 | -4 | 1/4" | 11,3 | 0,44 | 13,3 | 0,52 | 420 | 6,090 | 1,680 | 24,360 | 45 | 1,77 | 294 | 0,20 | MF+M00120-04 | OPF-04 |

| H10120010* | 10 | -6 | 3/8" | 17,6 | 0,69 | 20,0 | 0,79 | 420 | 6,090 | 1,680 | 24,360 | 100 | 3,94 | 699 | 0,47 | MF+M00910-08 | OPK-08 |

| H10120012* | 12 | -8 | 1/2" | 20,3 | 0,79 | 22,7 | 0,89 | 420 | 6,090 | 1,680 | 24,360 | 120 | 4,72 | 808 | 0,54 | MF+M00910-08 | OPK-08 |

| H10120016* | 16 | -10 | 5/8” | 23.9 | 0.94 | 26.4 | 1.03 | 420 | 6,090 | 1,680 | 24,360 | 140 | 5.51 | 997 | 0.67 | IP+M01500-10 | SP+M05400-10 |

| H10120019* | 19 | -12 | 3/4" | 27,7 | 1,09 | 30,2 | 1,19 | 420 | 6,090 | 1,680 | 24,360 | 150 | 5,91 | 1,307 | 0,88 | IP+M01500-12 | SP+M05400-12 |

| H10120025* | 25 | -16 | 1" | 35,0 | 1,38 | 37,5 | 1,48 | 420 | 6,090 | 1,680 | 24,360 | 210 | 8,27 | 2,031 | 1,36 | IP+M01500-16 | SP+M05400-16 |

| H10120031* | 31 | -20 | 1.1/4" | 44,7 | 1,76 | 49,5 | 1,95 | 420 | 6,090 | 1,680 | 24,360 | 260 | 10,24 | 3,701 | 2,49 | IP+M01600-20 | SP+M05500-20 |

| H10120038* | 38 | -24 | 1.1/2” | 53.2 | 2.09 | 56.4 | 2.22 | 420 | 6,090 | 1,680 | 24,360 | 310 | 12.20 | 4,498 | 3.01 | IP+M01600-24 | SPGX+M05500-24GX |

| H10120051* | 51 | -32 | 2” | 68.9 | 2.71 | 72.4 | 2.85 | 420 | 6,090 | 1,680 | 24,360 | 500 | 19.69 | 7,388 | 4.96 | IS+M02700-32 | – |

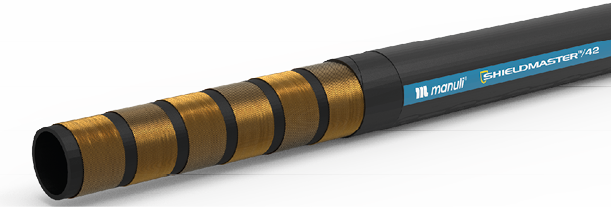

KEY FEATURES

• Outstanding abrasion and ozone resistance

• Compact and light structures

• Very low bend radius makes the product suitable for difficult installations

• Easy assembling and mounting operations (no protection sleeves required)

• Isobaric pressure rating

• Suitable for very cold environments

APPLICATIONS & FLUIDS

• High pressure hydraulic lines

• Heavy duty power lines

• High resistance to abrasion conditions, including rubbing among hoses in bunches, alternative to spring guards, easy cleaning in dusty environments

• For severe environmental conditions, long resistance to ozone and weathering, cold temperatures, dirty industrial environments

• Skive and no-skive fitting solutions

• Mineral oils, vegetable oils and synthetic ester based oils (up to 100°C/212°F), glycols and polyglycols, mineral oils in aqueous emulsion, water

CONTINUOUS SERVICE TEMPERATURE RANGE

-46 °C, -50 °F

100 °C, 212 °F

TUBE

Oil resistant synthetic rubber

REINFORCEMENT

Two high tensile steel braids (DN 6); Four high tensile steel spirals (DN 10-25); Six high tensile steel spirals (DN 31-51)

COVER

SHIELD

Composite bi-layer structure with outstanding abrasion and ozone resistance

APPLICABLE SPECS

ISO 18752 Type B

TYPE APPROVALS

MSHA, FRAS (requested); CU-TR

REMARKS

Applications with material projections or winding on low bend radius pulley systems should be field tested before use; high abrasion resistant rubber cover hoses are appropriate in most cases