|

TECHNICAL DATA |

|||||||||||||||

|

SIZE |

WORKING |

RATED FLOW |

OIL SPILLAGE |

MINIMUM BURST PRESSURE |

CONNECTION / |

||||||||||

|

DN |

inch |

Dash |

MPa |

PSI |

l/min |

US |

cc. |

cubic |

Male |

Female |

M & F |

||||

|

MPa |

PSI |

MPa |

PSI |

MPa |

PSI |

||||||||||

| 10 | 3/8 | 6 | 35 | 5,075 | 26 | 6.9 | 1.5 | 0.092 | 150 | 21,750 | 160 | 23,200 | 180 | 26,100 | Allowed |

| 12 | 1/2 | 8 | 30 | 4,350 | 54 | 14.3 | 2.0 | 0.122 | 130 | 18,850 | 140 | 20,300 | 140 | 20,300 | Allowed |

| 19 | 3/4 | 12 | 30 | 4,350 | 107 | 28.3 | 5.0 | 0.305 | 130 | 17,750 | 130 | 18,850 | 140 | 20,300 | Allowed |

| 25 | 1 | 16 | 25 | 3,625 | 186 | 49.1 | 9.0 | 0.549 | 110 | 15,950 | 110 | 15,950 | 110 | 15,950 | Allowed |

| 38 | 1.1/2 | 24 | 30 | 4,350 | 492 | 130.0 | 25.0 | 1.526 | 130 | 18,850 | 125 | 18,125 | 130 | 18,850 | Allowed |

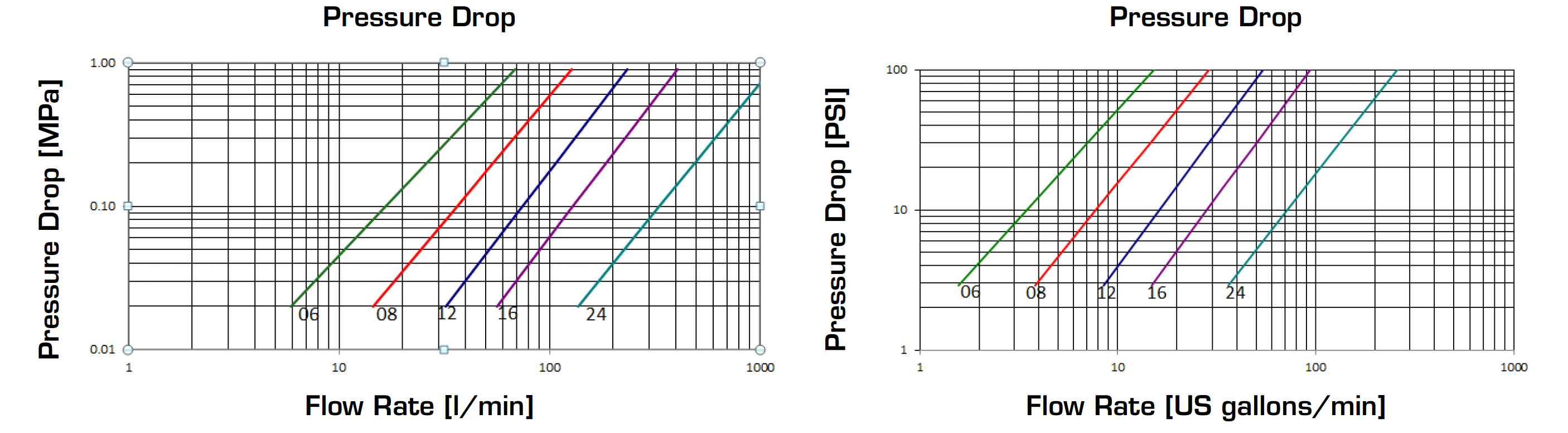

| The rated flow represents the normal operating condition. The maximum recommended flow rate is equal to 1.5 times the rated flow | |||||||||||||||

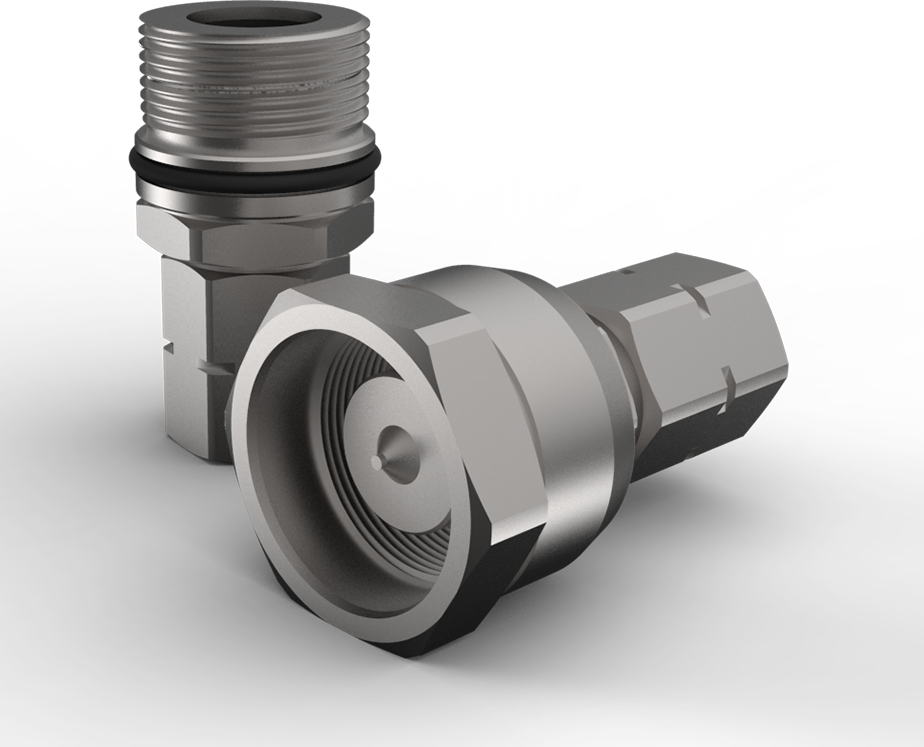

PRODUCT DESCRIPTION

• Screw-type couplings specially designed for heavy duty applications such as hammers, attachments, rock crushers, etc.

• Thanks to strengthened internal components this series is highly resistant against backflow, flow impulses and peaks, pressure impulses, vibration and hose bending

• Connection and disconnection is made by screwing the sleeve, also possible with rated pressure in the line

• Connection secured on the thread between the sleeve and the male coupling

• Shut-off by poppet valve

• Hexagonal profile of external sleeve for an easy connection and disconnection in high pressure conditions

• Interchangeable with MQS-SG series and similar products available on the market

• Up to size DN 20 ISO 14541 compliant

MATERIAL

Female and male coupling in high standard steel. Carbonitrided valve, springs in C98 steel, seals in NBR (other materials available on request) and back-up ring in PTFE

WORKING TEMPERATURE

-22ºF up to +230ºF (-30ºC up to +110ºC)

Specific seals available in case of higher temperatures

SAFETY FACTOR

4:1 for dynamic pressures

IMPULSE PRESSURES

200,000 cycles at 133% of the rated one (freq. 1Hz) disconnected; 500,000 connected

TEST SPECIFICATIONS

ISO 18869

| BSP | ||||

| Q06211041A / Q06111041A | ||||

|

Q06211041A Q06111041A |

||||||||||

| BSP TERMINATION ENDS TO DIN 3852 X TYPE |

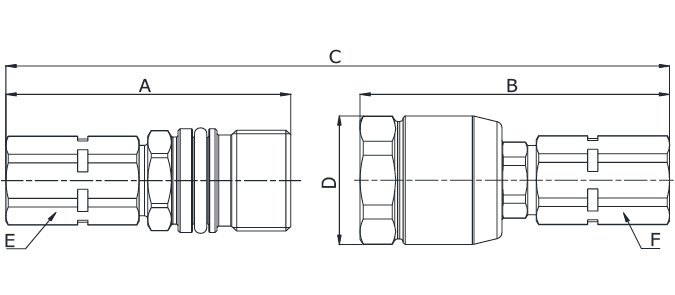

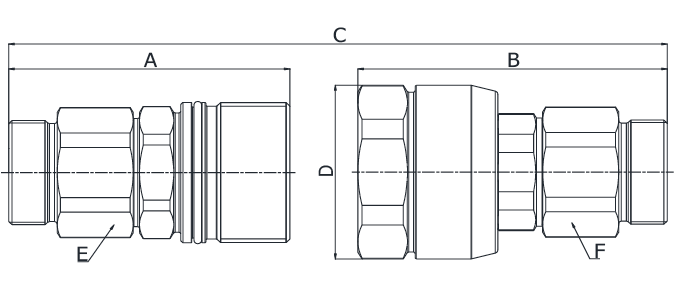

| SIZE | PART NUMBER | THREAD | DIMENSIONS mm | ||||||||

| DN | Inch | Dash | Female coupling | Male coupling | A | B | C | D | E | F | |

| 10 | 3/8" | -06 | Q06211041A-06-04 | Q06111041A-06-04 | 1/4" | 68 | 74 | A+B-26,5 | ⌀34,7 | 22 | 22 |

| 10 | 3/8" | -06 | Q06211041A-06-06 | Q06111041A-06-06 | 3/8" | 69.5 | 75.5 | A+B-26,5 | ⌀34,7 | 22 | 22 |

| 12.5 | 1/2" | -08 | Q06211041A-08-06 | Q06111041A-08-06 | 3/8" | 66.5 | 74.5 | A+B-26,5 | ⌀44,4 | 27 | 27 |

| 12.5 | 1/2" | -08 | Q06211041A-08-08 | Q06111041A-08-08 | 1/2" | 69.5 | 77.5 | A+B-26,5 | ⌀44,4 | 27 | 27 |

| 20 | 3/4" | -12 | Q06211041A-12-08 | Q06111041A-12-08 | 1/2" | 80.8 | 89.3 | A+B-31 | ⌀54,2 | 34 | 34 |

| 20 | 3/4" | -12 | Q06211041A-12-12 | Q06111041A-12-12 | 3/4" | 82.8 | 91.3 | A+B-31 | ⌀54,2 | 34 | 34 |

| 25 | 1" | -16 | Q06211041A-16-12 | Q06111041A-16-12 | 3/4" | 92.3 | 99.3 | A+B-34,5 | ⌀59,6 | 41 | 41 |

| 25 | 1" | -16 | Q06211041A-16-16 | Q06111041A-16-16 | 1" | 95.3 | 102.3 | A+B-34,5 | ⌀59,6 | 41 | 41 |

| 38 | 1-1/2" | -24 | Q06211041A-24-20 | Q06111041A-24-20 | 1.1/4" | 124.5 | 137.3 | A+B-47,5 | ⌀86,6 | 60 | 60 |

| 38 | 1-1/2" | -24 | Q06211041A-24-24 | Q06111041A-24-24 | 1.1/2" | 127.5 | 140.3 | A+B-47,5 | ⌀86,6 | 60 | 60 |

| METRIC | ||||

| Q06211870B Q06111870B |

Q06211120A Q06111120A |

|||

|

Q06211870B Q06111870B |

||||||||||

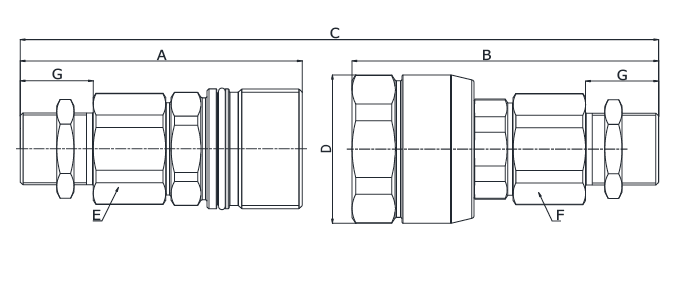

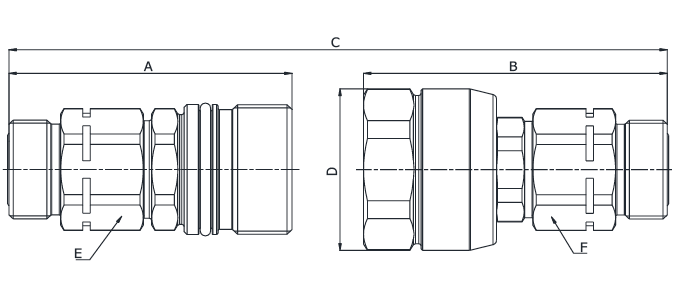

| METRIC TERMINATION ENDS BULKHEAD S SERIES |

| SIZE | PART NUMBER | THREAD | DIMENSIONS mm | |||||||||

| DN | Inch | Dash | Female coupling | Male coupling | A | B | C | D | E | F | G | |

| 38 | 1-1/2" | -24 | Q06211870B-24-42 | Q06111870B-24-42 | M42x2 | 146.7 | 159.5 | A+B-47,3 | ⌀86,6 | 60 | 60 | 38 |

|

Q06211120A Q06111120A |

||||||||||

| METRIC TERMINATION ENDS TO ISO 8434-1 S SERIES |

| SIZE | PART NUMBER | THREAD | DIMENSIONS mm | ||||||||

| DN | Inch | Dash | Female coupling | Male coupling | A | B | C | D | E | F | |

| 38 | 1-1/2" | -24 | Q06211120A-24-52 | Q06111120A-24-52 | M52x2 | 127.6 | 140 | A+B-47,3 | ⌀86,6 | 60 | 60 |

| ORFS | ||||

| Q06211240A / Q06111240A | ||||

|

Q06211240A Q06111240A |

||||||||||

| ORFS TERMINATION ENDS TO ISO 8434-3 |

| SIZE | PART NUMBER | THREAD | DIMENSIONS mm | ||||||||

| DN | Inch | Dash | Female coupling | Male coupling | A | B | C | D | E | F | |

| 25 | 1" | -16 | Q06211240A-16-16 | Q06111240A-16-16 | 1.7/16"-12 UN | 98.3 | 102.8 | A+B-34,5 | ⌀59,6 | 46 | 46 |