| TECHNICAL DATA | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|||||||||

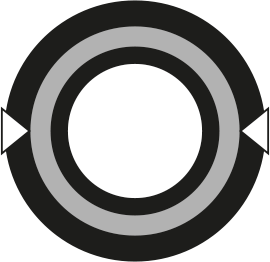

| PART REF. | HOSE SIZE | R.O.D | O.D | MAX. W.P | BURST | MIN. BEND | WEIGHT | FITTINGS | |||||||||

| DN | dash | inch | mm | inch | mm | inch | bar | psi | bar | psi | mm | inch | g/m | lb/ft | Std 1 | Std 2 | |

| H01060006* | 6 | -4 | 1/4" | 12.7 | 0.50 | 14.9 | 0.59 | 400 | 5,800 | 1,725 | 25,010 | 100 | 3.94 | 390 | 0.26 | MF+M00910-04 | OPF-04 |

| H01060008* | 8 | -5 | 5/16" | 14.3 | 0.56 | 16.5 | 0.65 | 350 | 5,070 | 1,480 | 21,460 | 114 | 4.49 | 435 | 0.29 | MF+M00910-05 | – |

| H01060010* | 10 | -6 | 3/8" | 16.7 | 0.66 | 19.0 | 0.75 | 330 | 4,780 | 1,400 | 20,300 | 127 | 5.00 | 530 | 0.36 | MF+M00920-06 | – |

| H01060012* | 12 | -8 | 1/2" | 19.8 | 0.78 | 22.0 | 0.87 | 275 | 3,980 | 1,200 | 17,400 | 178 | 7.01 | 640 | 0.43 | MF+M00910-08 | – |

| H01060016* | 16 | -10 | 5/8" | 23.0 | 0.91 | 25.2 | 0.99 | 250 | 3,620 | 1,020 | 14,790 | 200 | 7.87 | 760 | 0.51 | MF+M00910-10 | – |

| H01060019* | 19 | -12 | 3/4" | 27.0 | 1.06 | 29.0 | 1.14 | 215 | 3,110 | 900 | 13,050 | 240 | 9.45 | 940 | 0.63 | MF+M00930-12 | – |

| H01060025* | 25 | -16 | 1" | 34.8 | 1.37 | 37.0 | 1.46 | 175 | 2,530 | 700 | 10,150 | 300 | 11.81 | 1,350 | 0.91 | MF+M00930-16 | – |

| H01060031* | 31 | -20 | 1.1/4" | 44.3 | 1.74 | 47.0 | 1.85 | 150 | 2,170 | 600 | 8,700 | 420 | 16.54 | 2,010 | 1.35 | MF+M00920-20 | – |

| H01060038* | 38 | -24 | 1.1/2" | 50.7 | 2.00 | 53.4 | 2.10 | 100 | 1,450 | 410 | 5,940 | 500 | 19.69 | 2,250 | 1.51 | MF+M00910-24 | OPK-24 |

| H01060051* | 51 | -32 | 2" | 63.5 | 2.50 | 66.2 | 2.61 | 90 | 1,300 | 370 | 5,360 | 630 | 24.80 | 3,080 | 2.07 | MF+M00910-32 | OPK-32 |

KEY FEATURES

• Wide range temperature resistance

• EN/DIN and new SAE pressure rating

• Outstanding ozone resistance

• Superior weather and UV resistance

• High aging resistance

APPLICATIONS & FLUIDS

• Hydraulics: medium-high pressure lines in extreme temperature conditions (foundries, compressors, hydraulics within engine compartments, etc.)

• Mineral oils, glycols and polyglycols, transmission fluids, air with oil vapours, mineral oils in aqueous emulsion (up to 212°F/100°C)

CONTINUOUS SERVICE TEMPERATURE RANGE

-55 °C, -67 °F

135 °C, 275 °F

MAX. OPERATING TEMPERATURE

150 °C, 300 °F

TUBE

Oil resistant synthetic rubber

REINFORCEMENT

Two high tensile steel braids

COVER

STANDARD – TYPE “XT”

Synthetic rubber with high ozone, weather and heat resistance

APPLICABLE SPECS

Exceeds EN 853 2SN; SAE 100 R2AT; ISO 1436 2SN/R2AT

TYPE APPROVALS

ABS; DNV-GL; CU-TR; LR; MSHA; DNV-GL(MED)

REMARKS

• Compressed air applications require cover pin-pricking and additional safety devices. High pressure compressed air applications must be carefully analysed to verify the suitability of the hose, contact Manuli Hydraulics Help Desk for technical guidelines.

• Equator hose is not suitable for high temperature water applications

• Equator hoses are not designed and not approved for “air brake” applications on railway and/or mobile equipment